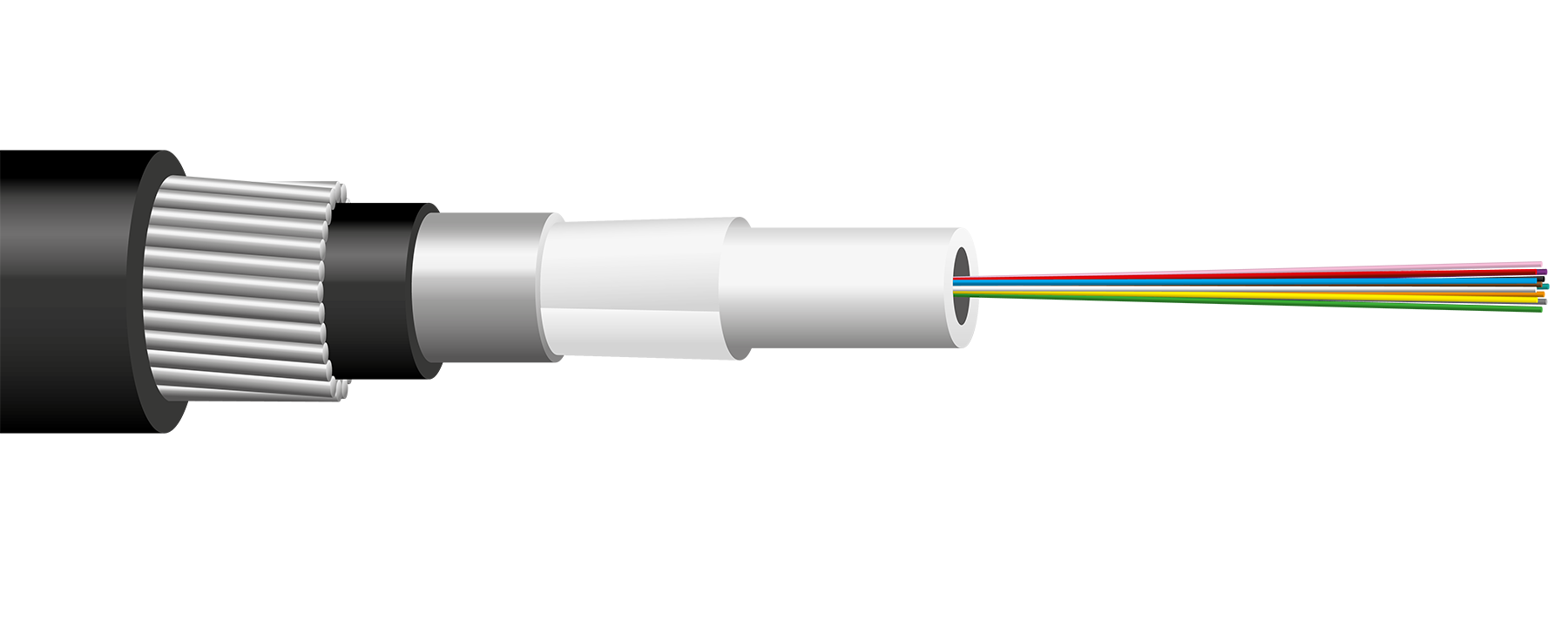

When optical fibre cable routes are constructed, sometimes watercourses have to be crossed or for terrain reasons even long sections of optical fibre cables have to be laid in a watercourse. In the case of small ditches or brooks the cable type has not to be changed and a directly buried cable is installed underground, but in other cases a stronger cables, underwater cables, must be used. Underwater cables shall be more heavy than typical directly buried cables in order to sink to the bottom of the watercourse. In addition, the cables shall withstand water pressure and on shores also the compression forces caused by rocks and ice. Underwater cables have a strong steel wire armouring, which makes those heavy and strong. The cable core construction is a compression resistant central tube. On shore, where the underwater cable comes from water to ground the cable is jointed to a directly buried cable. In the joint the steel wires shall be fixed in a reliable way and shall be earthed.

Underwater cables

Nestor Cables underwater cables are armoured with either 1,6 or 2,5 mm steel wires. Stronger 2,5 mm wires are used in cables, which shall be more heavy and mechanically strong. Such cable is FYOHBMP2,5JW with 96 fibres. Lighter cable FYOHBMP1,6MW has 1,6 mm steel wires and it is available as 12-, 24-, 48- and 96- fibre cable.

Beach closures

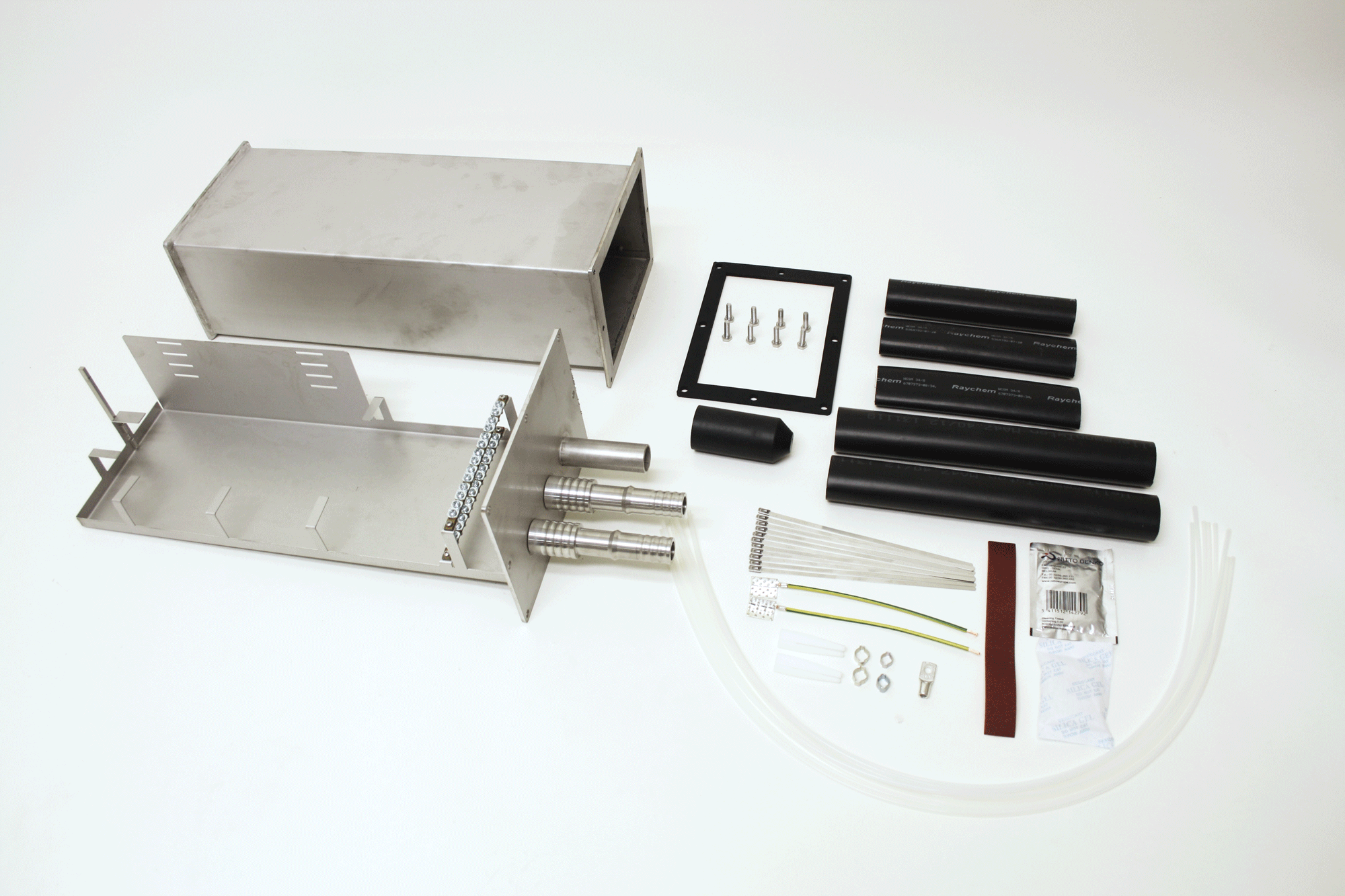

Based on NC-400 joint closure Nestor Cables has developed a beach closure NC-400W, which is provided with two cable entries for underwater cables and one entry for common directly buried cables. The closure includes accessories for the cable entries, steel bandage for fixing the armouring wires of underwater cables and SPA branching kit for splicing to fibres of a central tube cable. Splice trays and splice protection sleeves shall be ordered separately. For example universal splice tray NC-48S is suitable for this.

![[NAME]](https://www.nestorcables.com/media/layout/img/logot-ja-kuvat/nestor-cables-logo-white.png)